Infrastructure

🔶 With state of art technology and high end machinery, we can exceed customer expectations both in terms of quality and lead time.

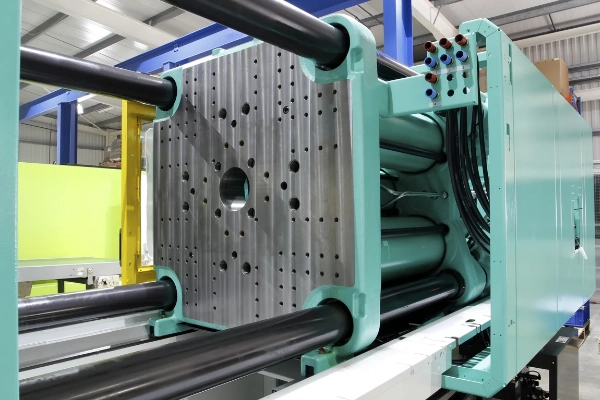

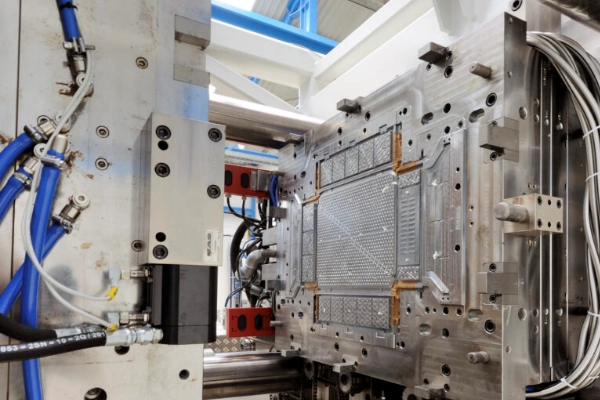

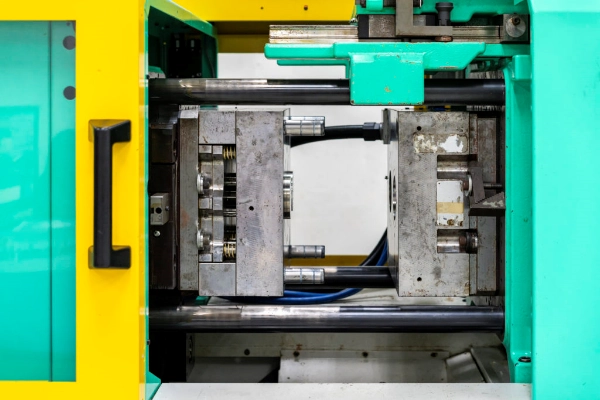

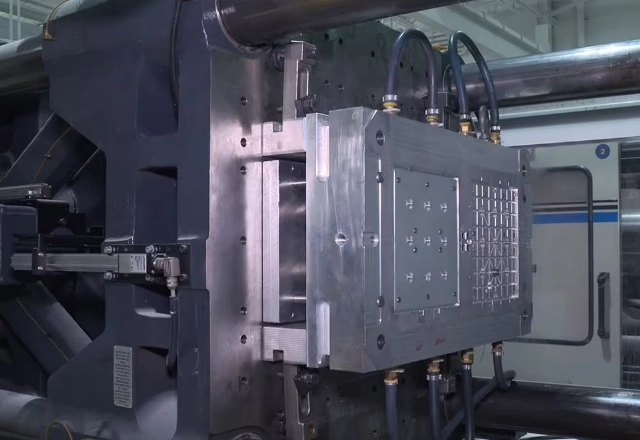

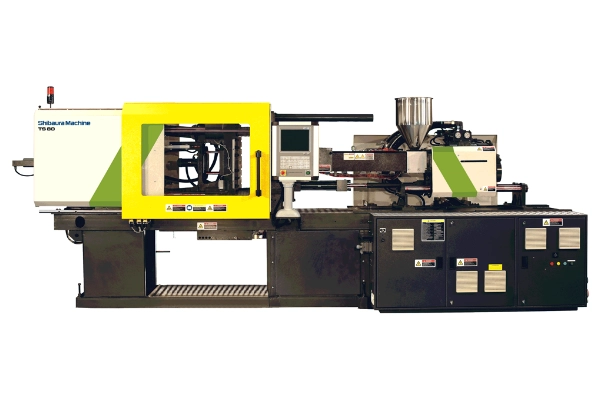

🔶 We have 5 numbers of state of art Injection Moulding machines from L&T Demag I Ltd and Shibaura machines Ltd.

🔶 The machines are ranging from 60 Tonnes to 125 Tonnes capacity.

🔶 We can produce components from 50gms to 210 gms shot weight.

🔶 The maximum distance between the tie bars of the machines are 460×460 mm.

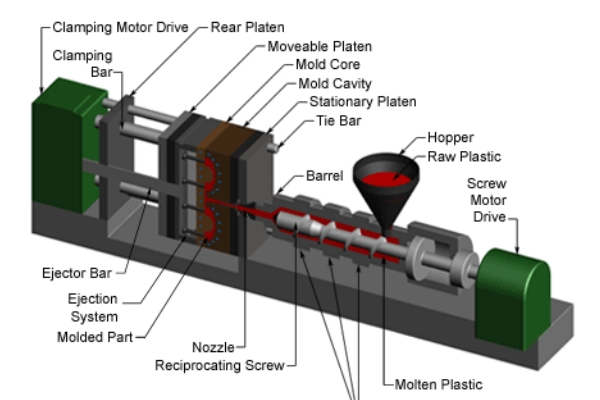

🔶 The screw diameter of all our machines are 35mm.

MACHINE SUPPLIER

🔶 Shibaura Machine

🔶 L&T Demag

POLYMERS PROCESSED

🔶 FLAME RETARDANT POLYCARBONATE

🔶 ABS

🔶 HIPS/PS

🔶 NYLON 6, NYLON 66

🔶 PBT

MATERIAL SUPPLIER

🔶 SABIC

🔶 COVESTRO

🔶 LOTTE

🔶 BHANSALI ENGINEERING

What we use to Manufacture our Products

Materials

The variety of different thermoplastics from basic commodity polymers to advanced and specialized engineering grades is vast.

We have the expertise to advise on materials suitability and carry out necessary trials. You do not have to worry about venturing into the unknown.

Our experts will be there to advise and assess every step of the way.

Our strong relationships with a number of polymer distributors enable us to pass on speedy and cost effective material supplies to our clients as well as keep upto date with new advances in thermoplastic technology.

Polycarbonate PC Plastic

Polycarbonates are a group of thermoplastic polymers containing carbonate groups in their chemical structures.

Polycarbonates used in engineering are strong, tough materials and some grades are optically transparent. They are easily worked, moulded and thermoformed.

Properties of PC:

- Highly impact resistant at least 250 times stronger than glass.

- Light Transmittance.

- Easy to shape

- Suitable for intensive use.

- Resistance to high temperatures

- Bondable

- Easy to process

- Unbreakable and non-flammable

Modular Switches SP CARB PC grades compounds consist of high gloss, spark shield inside them to conceal high sparking and avoiding any damage or short circuiting due to leakage of current, insulation resistance, shock proof and easy to remove or refit and of the same brand as that of a modular switch.

PC PROCESSING

- MELT TEMPERATURE is 270 to 300 deg C

- INJECTION SPEED: Relatively fast injection moulding, such as parts of electric switches, is usually adopted.

The injection molding usually shows a slow to high-speed pattern.

PC has a high water absorption rate, so it has to be preheated and dried before processing. It is recommended that the pure PC is dried at 120 deg C for 3 hours.

Usually an empty shot is performed to see whether it is sufficiently dried.

The proportion of Recycled PC can reach upto 20%.Under some circumstances 100% recycled material is allowed with the actual proportion depending on the product quality requirements.

The recycled material cannot be concurrently mixed with different masterbatches otherwise the properties of the final product will be seriously compromised.

Mold and Gate Design

- The commonly used mold temperature is 80 deg C to 100 deg C for PC and 100 deg c to 130 deg C for reinforced PC.

- The pinpoint gate is usually used for small sized products and gate depth should be more than 70% of the thickest part.

- Other gate types include ring gate and rectangle gate.

- The larger the gate, the better so as to minimize defects caused by excessive plastic shearing.

- The depth of vent holes should be less than 0.03 to 0.06 mm, the runner should be designed as short and round as possible and the draft angle usually stands at around 30’ – 1 deg.

BACK PRESSURE

The back pressure of about 10 bar is recommended which can be appropriately reduced when there are no jetting marks or color mixing.

RESIDENCE TIME

- If the residence time at a higher temperature is too long, the material will be degraded with CO2 released and color turning into yellow.

- Use PS instead of LDPE, POM, ABS, PA to clean the barrel.

ABS

- ABS is a light yellow opaque pellets with high surface gloss.

- The specific gravity of ABS is 1.05g/cc, slightly heavier than water. It possesses the characteristics of high toughness, hardness and rigidity.

- ABS combines well with other materials and is easy to surface print, coat and plate.

- ABS boasts excellent mechanical propertis. Its outstanding impact strength allows it to be used under extremely low temperature conditions.

- ABS is highly wear resistant, dimensionally stable and oil resistant.

- ABS boasts great electrical insulation and is hardly affected by temperature,humidity and frequency so it can be used in most environments.

- ABS material is hygroscopic and requires to be dried during processing.

- Suggested drying conditions 80 -90 deg C for not less than 2 hrs.

- Melting Temperature 210 to 280 deg C

- Mold Temperature 25 to 70 deg c

- Injection Pressure 500 to 1000bar

- Injection Speed medium and high speed.

- ABS products are easy to carry static electricity and the surface is easy to attract dust.

- Its shrinkage ranges between 4% and 8%.

PA (NYLON)

- The name Nylons refers to the group of plastics known as polyamides.

- The majority of Nylons tend to be semi crystalline and are generally very tough materials with good thermal and chemical resistance.

- Nylon 6 and 66 are both synthetic polymers called polyamides.

- Nylon 6 should be used if a lightweight engineering plastic is required to withstand high impact and stress.

- Nylon 6 has better aesthetic appearance than Nylon 66 due to its lustrous finish and is easier to dye.

- Nylon 66 should be used if a high performing engineering plastic is required that will be exposed to higher temperatures. Additionally, its stiffness and good tensile and flexural modulus make it an ideal material for applications that need repeated long term performance.

CORE PROPERTIES

- High mechanical strength, stiffness, hardness and toughness

- Good fatigue resistance.

- High mechanical damping ability

- Good sliding properties.

- Excellent wear resistant.

- Good electrical insulating properties

- Good resistance to high energy radiation

- Good machinability

NYLON 6/66 APPLICATIONS

- Nylon 6/66 possesses good electrical insulation properties making it suitable for electrical and electronic applications used in wire insulation, connectors and circuit board components, circuit breakers and electronic hosings.

- They find applications in automotive components, consumer goods and aerospace industries.

PBT (POLYBUTYLENE TEREPTHALATE)

PBT is a semi crystalline white or off white polyester similar in both composition and properties to PET. It has somewhat lower strength and stiffness than PET, is a little softer but has higher impact strength and very similar chemical resistance.

As PBT crystallises more rapidly than PET, it tends to be preferred for industrial scale moulding. Applications of PBT include electrical and automotive components.

KEY PROPERTIES:

- Excellent chemical resistance

- Excellent machining characteristics

- Good electric insulation

- Superior dimensional stability

- Low moisture absorption

- Good heat resistance

- Stain resistance

- Good strength and stiffness

- Excellent resistance to creep.

APPLICATION OF POLYCARBONATE ALLOYS

- PC/ABS Alloys : The PC and ABS blend integrates the excellent properties of both PC and ABS, improving the heat resistance, impact resistance and tensile strength of ABS, lowering the cost of PC and melt viscosity, improving processability and reducing product internal stress and the sensitivity of impact strength to product thickness.

- PC/PBT Alloys: PBT boasts excellent mechanical properties, great resistance to chemical corrosion and easy injection moulding.

The alloy is made by blending PBT and PC are able to improve the fluidity, processability and chemical resistance of PC. Since PBT is a crystalline polymer,phase separation is easy to occur when blended with PC with unsatisfactory interfaced adhesion, so it’s impact toughness is not ideal. Usually a certain amount of elastomer is added to improve the impact strength of the blend. For eg,the zinc salt of the thermoplastic elastomer ethylene co polymer has a compatibilizing and toughening effect on the PC/PBT blend.

Services

PLASTICS INJECTION MOULDING is the primary service we provide. Reliability, quality and value for money are the hallmarks of our plastic injection moulding service.

🔶 Injection moulding of polycarbonate switches, sockets, spark shields, and cover plates.

🔶 Injection moulding of abs door bell, flex box, multiplug/plug tops, plastic gang box.

🔶 Injection moulding of pendant holders, batten holders, ceiling roses, square box.

🔶 Injection moulding of power strip and spike guards.

Injection Moulding Machines